ISOCLEAN® reliability

What's really at stake when hydraulic equipment fails?

If you’re focused on maximizing your operation’s output, you know that using clean lubricants and following proper lubricant storage and handling practices is the best way to maximize equipment life. But between pressures from business leaders to do more with less and your own laundry list of boxes to tick and goals to meet, it’s not always easy to recognize the right path forward—let alone follow it. Your business is complex, but getting more from your hydraulic equipment doesn’t have to be. The lubricant choices you make today have a direct effect not only on your equipment life and reliability, but also on your business’s bottom line, its reputation and its long-term success.

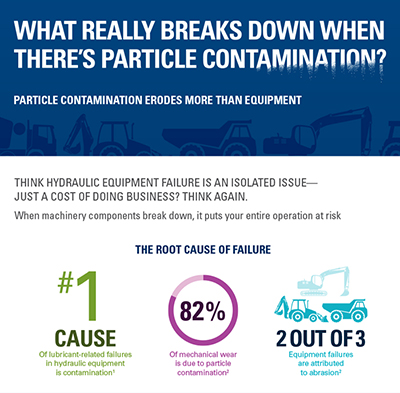

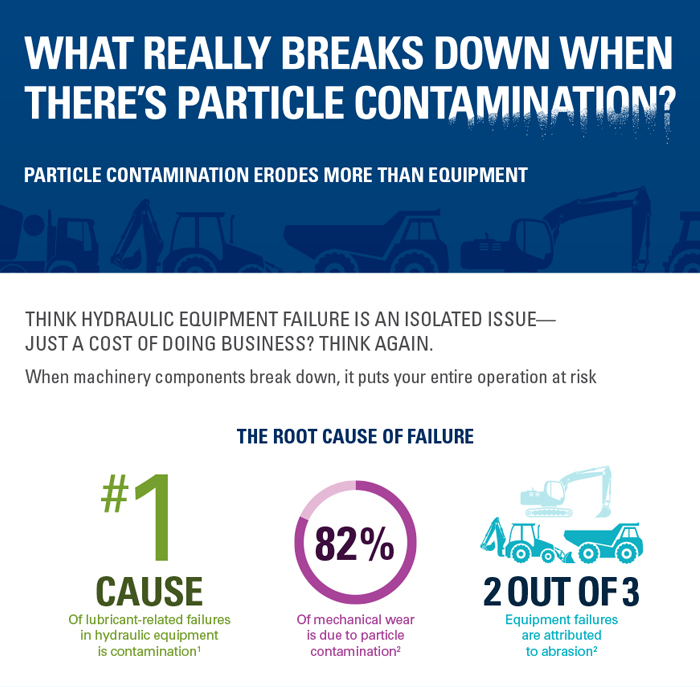

Identifying the source

Dirt. Grime. Gunk. Whatever you call it, particle contamination can spell disaster for hydraulic systems. It's estimated that 82% of wear is particle-induced, with abrasion wear accounting for two-thirds of that figure. It comes down to the tight working clearances between hydraulic parts. Even a tiny number of particles invisible to the naked eye can grind the integrity of a machine until it ultimately breaks down.

The snowball effect

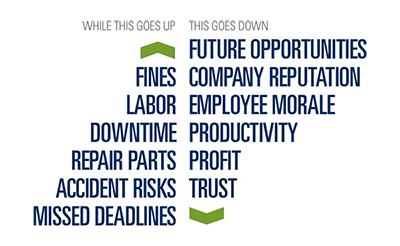

The precision component interaction of hydraulic machinery means that multiple parts have to work together seamlessly to perform at their best. So when part of the system struggles or fails, the whole machine does too. But the cost goes far beyond parts and labor. In highly competitive industries like construction and mining, equipment failure can create a disadvantage that can be impossible to recover from.

There’s more at stake than a single piece of equipment

When machines are sidelined by breakdown, a business-wide chain reaction begins.

The solution is prevention

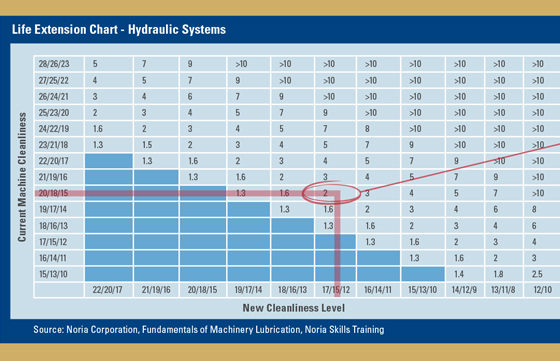

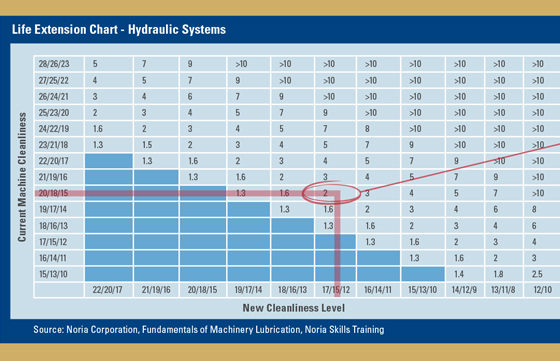

Controlling contamination starts with a certified lubricant that meets OEMs’ ISO Cleanliness specifications, the standardized coding system used to measure particle contamination. Starting clean is the best way to protect your equipment, your business’s reputation and your bottom line. Only Chevron ISOCLEAN® Certified Lubricants are delivered to exact ISO Cleanliness specifications, maximizing equipment reliability and uptime along with your own peace of mind.